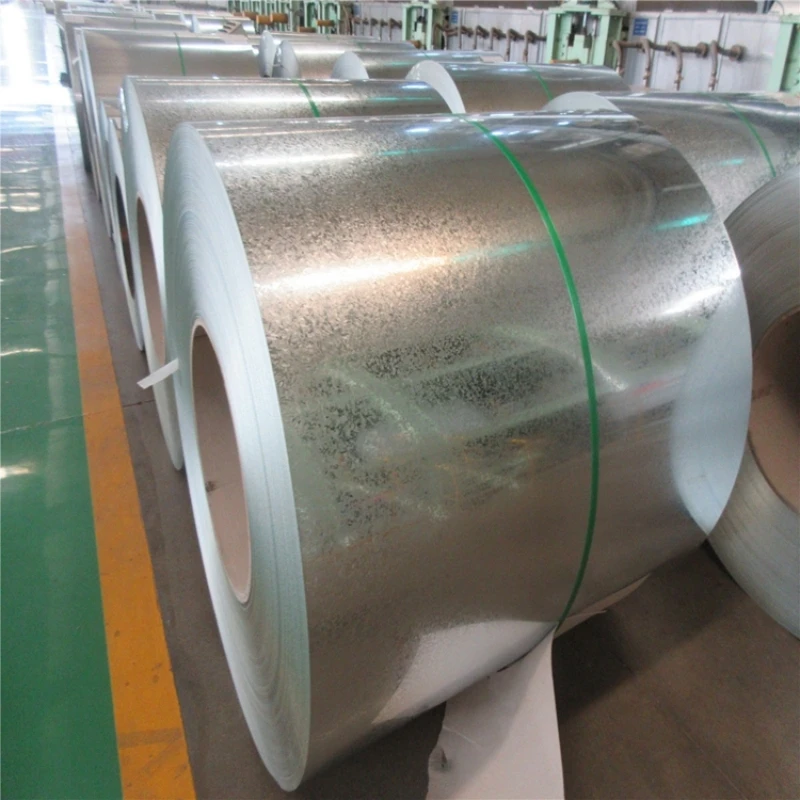

Hot - Dipped Galvanized Steel Coil for Enhanced Protection

Due to our hot dipped galvanization process, our steel coils have a thick as well as a uniform layer which ensures low rates of corrosion. Because of this, it makes the product ideal to be used in extreme conditions and assures longevity.